FLANGES

VL Flange provides a wide variety of ASME code and Non-Code Industrial Flanges for the petrochemical, valve, pressure vessel, heat exchanger, oil refinery, process, nuclear, pipeline and mining industries. Slip-on flanges, weld neck flanges, blind flanges, lap joint flanges, orifice flanges, long weld neck flanges and threaded pipe flanges are some basic styles we provide. Our flanges come in many material grades such as carbon steel, low temp, stainless steel, nickel alloy, Chrome Moly and duplex. We also custom manufacture sizes ½” up to 250” in diameter based per our clients requirements and specifications.

ANSI B16.5 Flanges

Weld Neck, Slip-On, Socket Weld, Threaded, Lap Joint, Blind

1/2″ – 24″

• Class 150

• Class 300

• Class 400

• Class 600

• Class 900

• Class 1500

• Class 2500

Orifice Flanges

Weld Neck, Slip-On, Threaded

• Class 300

• Class 400

• Class 600

• Class 900

• Class 1500

• Class 2500

Long Welding Necks

• Class 150

• Class 300

• Class 400

• Class 600

• Class 900

• Class 1500

• Class 2500

ANSI B16.47 Flanges Weld Neck, Slip-On, Blind.

• Class 75 – Ser. B

• Class 75 – Slip-On, Ind. Standard

• Class 75 – Weld Neck, Ind. Standard

• Class 125 – LW, AWWA C207 Class B, D

• Class 125 – LW, AWWA C207 Class E

• Class 150 – Weld Neck, Ser. A

• Class 150 – Weld Neck, Ser. B

• Class 175 – Ind. Standard

• Class 300 – Weld Neck & Blind Ser. A

• Class 300 – Weld Neck & Blind Ser. B

• Class 350 – Weld Neck, Slip-On Ind.

STANDARD

• Class 400 – Ser. A & B

• Class 600 – Ser. A & B

• Class 900 – Ser. A & B

Misc. Info

• Typical Facings for Steel Pipe

Flanges–Dimensions

• Typical Facings for Steel Pipe

Flanges–Drawings

• Facing Dimensions for Ring Joints (Class

150-2500)

• Ring Joint Dimensions–ANSI B16.47 Ser.

A 26″ thru 36″

• Bolt and Stud Dimensions (Class 150 –

2500)

• Bore Chart–Wall Thicknesses & Inside

Diameters

• Dimensional Tolerances

• Gasket Surface Finishes

• Ring Joint Gasket Dimensions

• Ring Numbers for Ring Joint Flanges

• Ring Joint Flange Facing Dimensions

• Threading Practice

• Beveling Standards

LONG WELD NECK FLANGES

Long Neck Welding (abbreviated LWN) flanges are similar to a standard Welding Neck flange, but the “Neck” is considerably longer. This type is often used as a nozzle for a barrel or column. In addition, there are the type LWN Heavy Barrel (HB) and the Equal LWN Barrel (E); they have a different shape and a thicker “Wall”.

Long Weld neck flange dimensions are covered in ASME B16.5 – which covers Pipe Flanges and Flanged Fittings for size NPS ½” to 24” for above NPS 26” to 60” it should be as per ASME B16.47.

Description of our product: NPS 1/2″ to 24″

- Pressure Rating: Class 150, Class 300, Class 600, Class 900, Class 1,500, Class 2,500

- Connection Face: RF, RTJ

- Materials: Carbon Steel, Stainless Steel, Alloy Steel

- Coatings: Oil, Black Paint, Yellow Paint, Hot Dip Galvanized, Elecrolytic Zinc and Epoxy Resin Coatings.

PIPE

We offer steel pipe that is largely used in various industries including water, petrochemical, refineries, power plants, nuclear, ship building and many more. Our pipe is resistant to high pressure and yield years of optimum performance and is available in many different grades. We also custom manufacture per our clients requirements and specifications.

Carbon Steel / Mild Steel Welded Pipes

● Pipes from Size: 1/2” NB/OD to 60” NB/OD, Thickness: Schedule 5 To XXS,

1.2mm to 60mm thick in following Grades & Specification API 5L X42, API

5L X46, API 5L X52, API 5L X56, API 5L X60, API 5L X65,API 5L X70

● LSAW PSL1, LSAW PSL2, DSAW PSL1, DSAW PSL2, Submerged Arc Welded

● API5LX-42, API5LX-46, API5LX-52, API5LX-56, API5LX-60, API5LX-65, API5LX-70

● PSL 1 LSAW, PSL 2 LSAW, PSL 1 DSAW, PSL 2 DSAW, Submerged Arc Welded

● API 5L Grade B LSAW, DSAW, HSAW, SPIRAL WELDED, ERW PSL1, PSL2

● API 5L X-42 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW PSL1, PSL2

● API 5L X-46 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW PSL1, PSL2

● API 5L X-52 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW PSL1, PSL2

● API 5L X-60 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW PSL1, PSL2

● API 5L X-65 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW PSL1, PSL2

● API 5L X-70 LSAW, DSAW, HSAW, SPIRAL WELDED, ERW PSL1, PSL2

● SA672 Grade A45, SA672 Grade A50, SA672 Grade A55

● SA672 Grade B55, SA672 Grade B60, SA672 Grade B65, SA672 Grade B70

● SA672 Grade C55, SA672 Grade C60, SA672 Grade C65, SA672 Grade C70

● SA672 Grade D70, SA672 Grade D80

● SA672 Grade L65, SA672 Grade L70, SA672 Grade L75

* STAINLESS STEEL PIPE

* DUPLEX AND SUPER DUPLEX PIPES & TUBES

* CARBON STEEL SEAMLESS PIPE

* ALLOY STEEL SEAMLESS PIPES & TUBES

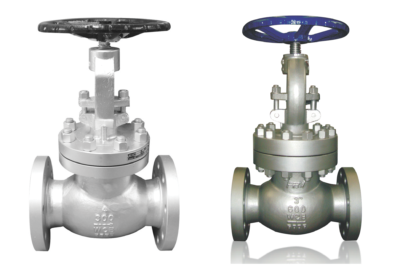

VALVES

Ball, Butterfly, Plug, Gate, Globe, Knife Gate and Check Valves

Bellows Seal, Flow Control, HF Acid, Relief and Diaphragm Valves

Specialty Products (Sampling Valves, Tank, Bottom, Specialty Valves, Steam Traps)

AVAILABLE BODY/TRIM MATERIALS:

Alloy 20, Aluminum Bronze, Bronze, Carbon Steel, Cast Iron, Ductile Iron, F5, F9, F11/F22, F91, Hastelloy C, Inconel, LF2, LCB,

LCC, Monel, Stainless Steel (316, 304, 304H, 347), WC6, WC9, C5, C12, C12A

Cast/Forged Steel

Vogt

Crane

Powell

Walworth

Edward

Stainless & Alloy

Aloyco

Powell

Ladish Valves

Velan

Cooper

Butterfly/Wafer Check

Centerline

Flowseal

Duo Check II

Ball Valves

Worcester

P.B.V.

NIBCO

Quadrant

McCanna

Plug Valves

Durco

Xomox

Nordstrom

BUTT WELD FITTINGS

VL distributes both domestic and foreign

forged steel pipe fittings. We also distribute

½” thru 60” butt weld fittings.

All fittings available in carbon, low temp, Chrome Moly, stainless steel, duplex, super duplex and nickel alloys.

We now also provide High Yield weld fittings from 42,000 to 70,000 psi minimum yield.

FASTENERS

When we talk about a fastener, we can term it as a hardware tool that automatically connects or joins two or more equipment’s together. This hardware tool is something which can be which can be easily fitted in and detached easily with the help of a hand tool or power tool. Fasteners generally consist of screws, bolts, nuts and rivets.

PURPOSE OF FASTENER

When we talk about the standard purposes of the fasteners, we divide that into two categories:

1 De-attaching for examination and restoration purpose.

2 Standard design, where a produce comprises of a number of sub-assemblies.

We are able to offer several plating solutions, including copper, phosphate, silver, zinc, zinc-nickel, and electroless nickel plating. Each of these solutions comes with its own unique qualities, allowing us to customize your desired products to function more efficiently and more durable than it would in its standard state.

Our coating solutions include spray coating, thermal spray aluminum/zinc, phosphate, and blasting. Through these processes, we are able to accommodate a wide range of customizable options to meet your unique specifications.

GASKETS

In piping, a Gasket is sealing material placed between connecting flanges to create a static seal, which will maintain the leakage proof sealing in all operating conditions. Different types of gaskets are used to achieve the leak proof sealing between the pipe flange. The primary function of gaskets is to seal the irregularities of each face of the flange so that there will be no leakage of the service fluid from the flange joint.

Types of Gaskets:

There are three types of gaskets used in process piping.

- Non-Metallic

- Metallic

- Composite

We specialize in all kinds of material including Neoprene, Nitrile, EPDM, Viton, Non-Asbestos, Plant Fiber, Closed Cell Foam, Silicone, Silicone Sponge, Graphite, and Polytetrafluoroethylene to name a few

VL FLANGE

Why choose VL Flange?

We can supply you with anything, yes ANYTHING

At VL Flange it is our mission and priority to provide our

customers not only with great customer support, but also to

supply their needs with any kind of materials. It’s what

makes us unique! This way you can shop all in one place.

YOU NEED YOUR MATERIALS DELIVERED TO YOUR PORT?

Ready to Talk?

No matter what you require, we are the ones to talk to regarding all issues of your project.

WE WILL DO ANYTHING TO CARRY OUT YOUR PROJECT SUCCESSFULLY

We have excellent expert knowledge and are able to support you even in technical matters