PIPE THREADING

Threaded pipes can provide an effective seal for pipes transporting liquids, gases, steam, and hydraulic fluid. We thread any length of pipe in diameters ranging from 1/8” to 20”. Tapers available are NPT*, NPS*, 3/16” Peerless, and 8 round taper. (See fabrication services page for larger diameters).

*National Pipe Thread is a U.S. standard for tapered (NPT) or straight (NPS) threads used to join pipes and fittings. ANSI/ASME standard B1.20.1 covers threads of 60-degree form with flat crests and roots in sizes from 1/16 inch to 24 inch Nominal Pipe Size. The taper rate for all NPT threads is 1/16 (3/4 inch per foot) measured by the change of diameter (of the pipe thread) over distance. The taper divided by a center line yields an angle 1° 47′ 24″ or 1.7899° as measured from the center axis.

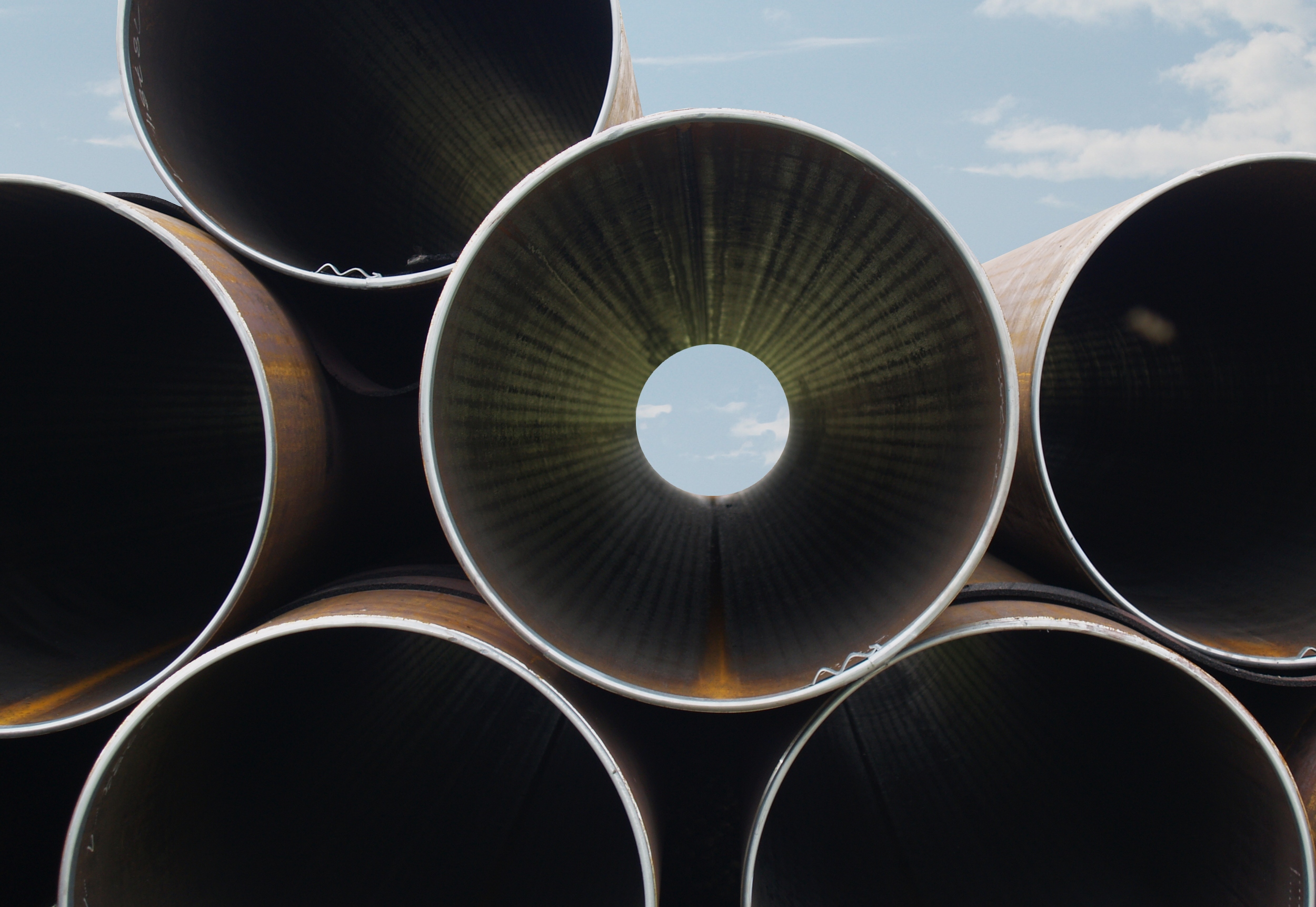

PIPE COATING

VL Flange can provide a variety of protective coating and lining services. Some of the most common coating & lining services are FBE (Fusion Bond Epoxy), Synergy Wrap, Scotch Coating (Fletcher Coating), Spiral Wrap and Galvanizing. Common lining types are FBE (Fusion Bond Epoxy) & Cement lining. These coatings are widely used to protect the steel pipe used in pipeline construction, reinforcement steel, and on a wide variety of piping connections. This protective layer of coating helps prevent corrosion, which can lead to leaks, service interruptions, and even explosions of the steel wall. The pipe size range for these services are normally 1/8” OD and up. Traditionally, this service is order specific.

PIPE BEVELING

Beveling is the process in which we form an angle between the edge of a pipe and a plane perpendicular to the surface to a certain degree, most commonly used to prepare the ends of pipes for welding. Beveling can also be used for deburring the cut tends for safety and aesthetic reasons. We can apply any type of bevel to any degree required. Beveling can be applied to the face of any size or diameter of a pipe.

PIPE CUT AND ROLL GROOVING

Vl Flange provides both cut grooving and roll grooving. Cut and roll grooving can be done in any style according to industry standards. Cut grooving can be applied to any length of pipe ranging from ½” to 20” in diameter with a minimum length of 2 ½”. Roll grooving can be applied to any length of pipe ranging from 2” to 24” in diameter with a minimum length of 6″.